Laminating, concealing or UV protection? This is how you protect your prints optimally

Wednesday, January 1, 2025

Prints are more than just information on paper – they represent your ideas, brands or messages. But without the right protection, even the highest quality prints can quickly lose quality and impact. In this article we will show you what protection methods there are and how you can find the optimal solution for your individual requirements.

Prints are more than just information on paper – they represent your ideas, brands or messages. But without the right protection, even the highest quality prints can quickly lose quality and impact. In this article we will show you what protection methods there are and how you can find the optimal solution for your individual requirements.Why is protection important for prints?

Prints, whether posters, flyers or business cards, are often exposed to environmental influences such as moisture, UV radiation or mechanical stress. Without proper protection, colors can fade, surfaces can become damaged, and the longevity of the print will suffer significantly. Choosing the appropriate protection method is crucial to preserving the quality and impact of your prints in the long term.The protection methods in comparison

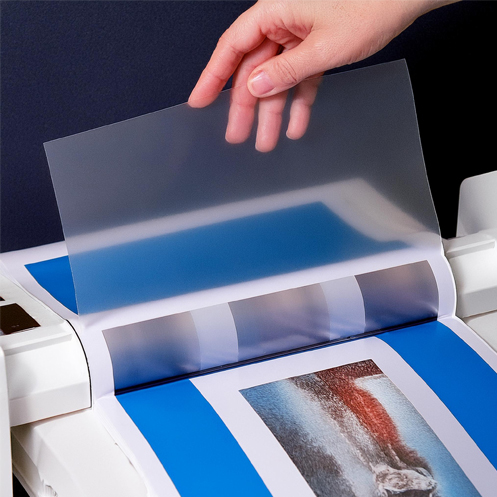

Today there are three methods to protect prints from external influences: laminating, concealing and UV protective varnish. Let's take a closer look at their advantages and disadvantages.Laminating

When laminating the print is covered on both sides with a thin film that is applied under heat or pressure. The lamination offers a very high level of protection against moisture and dirt and increases stability thanks to the double-sided film. The surface can be chosen to be matt or glossy depending on the visual requirements. This process is ideal for heavily used documents such as menus or ID cards.However, laminating also has disadvantages. It is not environmentally friendly because it uses a plastic film. Additionally, the print is permanently sealed, which cannot be reversed. This method is more expensive than other methods.

Concealing

Concealing is similar to laminating, but the print is only covered with a protective film on one side. This method is often used for posters or acrylic glass signs. The concealation offers an elegant surface look such as soft touch or high gloss. The process protects against scratches and UV radiation and can be used flexibly on different materials.Compared to laminating, concealing offers the print less protection from moisture and is sensitive to strong mechanical stress.

UV protective coating

With this protection method, a special layer of varnish is applied to the print, which protects it from UV radiation and light mechanical stress. The UV protective varnish can be glossy, matt or structured. The varnish protects very effectively against color fading caused by UV radiation and at the same time gives the print a high-quality finish. The process is also more cost-effective than laminating or concealing and is more environmentally friendly as no films are used.The disadvantages of this process include less protection of the print from moisture and dirt. In addition, the UV protective varnish is less resistant to mechanical stress.

Additional tips for optimal pressure protection

How can you optimize print protection? Here are some additional tips:1. Use combinations.In some cases it may make sense to combine several protection methods, for example laminating with UV protective varnish, to achieve maximum longevity.

2. Proper StorageStore your prints in a dry environment to minimize the risk of moisture damage.

3. Quality ControlWork with experienced print service providers who offer high-quality protection methods.

Also remember that the choice of protection method depends on the intended use and environmental influences:

✔

Laminating is suitable for documents that are heavily used or are transported frequently;✔

Concealing is ideal for prints that need to appear high-quality and, above all, need to be protected from UV radiation;✔

UV varnishing is recommended for cost-effective applications where color protection is a priority.