Artificial glass - what types are there?

Monday, June 1, 2020

Transparent plastics, which are often offered as craft glass , art glass or acrylic glass , are conquering the market. It is difficult for the layman to distinguish between the different varieties. You are wondering what the differences are between Plexiglas® and acrylic glass. Or what is hidden behind letter combinations such as PMMA, PC, PS and GS. This text introduces you to the mysteries of artificial glasses.

The most important transparent plastics are polymethyl acrylate (PMMA, acrylic glass ), polycarbonate ( PC ), polystyrene ( PS ), polyethylene terephthalate ( PET ) and styrene-acrylonitrile copolymers ( SAN ). Other designations are just brand names such as PLEXIGLAS®, others refer to the manufacturing process (such as GS for "cast" or XT for "extruded").

Other brand names for acrylic glass are Piacryl®, Deglas®, Hesalitglas®, Limacryl®, PerClax® and Vitroflex®.

The material was developed independently in different countries in 1928. It was first used in contact lenses in 1940. The hood of the Braun SK 4 turntable combinations was the first everyday product made of acrylic glass. It was launched in 1956.

The material is easy to color, weatherproof and aging resistant. Although acrylic glass is translucent , it absorbs UV rays and is therefore UV stable . However, it is more scratch-sensitive than glass or polycarbonate, but it can be polished to remove scratches .

When cleaning , it should be noted that although acrylic glass is resistant to acids, medium-concentration alkalis, petrol and oil, ethanol, acetone and benzene dissolve it.

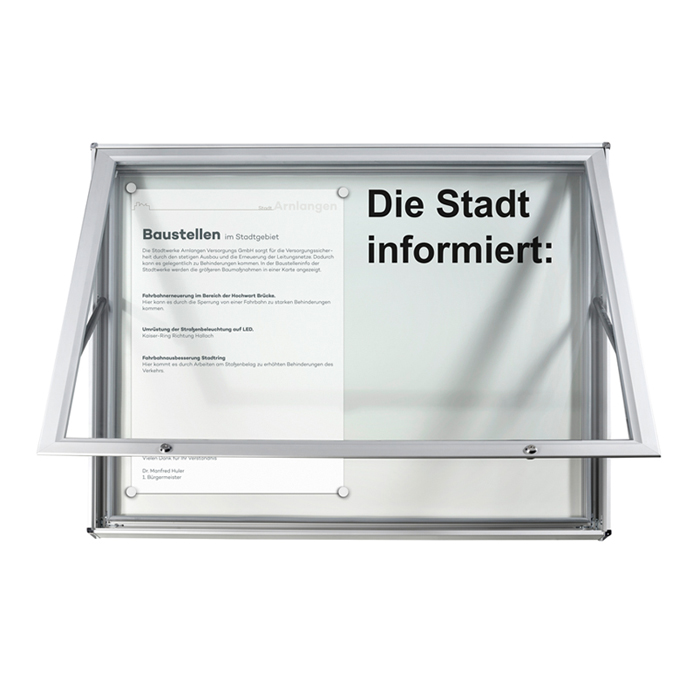

Acrylic glass is more suitable for signs and advertising materials than other types of art glass because of its more attractive appearance and crystal-clear transparency.

The chemist Alfred Einhorn discovered the material as part of his research as early as 1898. However, since he was involved in the development of narcotics, the substance did not interest him. It was not until 1953 that Bayer AG developed the plastic further and brought it onto the market as Makrolon® in 1958. In 1973 General Electric began manufacturing under the trade name Lexan®.

PC is less UV stable (yellowed) than acrylic glass. In practice, the higher scratch resistance and better resistance to chemicals compared to acrylic glass are important. PC can also be bent cold . Another advantage of PC compared to acrylic glass is its higher impact resistance and fire behavior. Polycarbonate panels meet the fire protection standard DIN 4102 B1 .

Due to the higher price (two to three times more expensive) and the lower transparency (PC scatters the light), the material is more likely to be used in aircraft windows, car headlight glass and greenhouse glazing, since break resistance and scratch resistance are important here. A typical product made of polycarbonate in the private sector is transparent corrugated sheets and double-wall sheets for cladding, as well as CDs and DVDs.

PS does not splinter and can be easily processed like acrylic glass - whether cutting, sawing, drilling or gluing. In some cases, PS is even easier to work with than acrylic, which is why this material is also suitable for beginners.

In contrast to acrylic glass, however, polystyrene is absolutely not UV-compatible . It is therefore only suitable for indoor use.

SAN has higher strength , thermal resistance and scratch resistance than acrylic glass, but is less UV-stable , has lower impact strength and a slightly yellowish tint. Unlike polycarbonate, it is not suitable for clipping. Common brand names are Luran®, Lustran®, Styvex® and Suprel®.

The most important transparent plastics are polymethyl acrylate (PMMA, acrylic glass ), polycarbonate ( PC ), polystyrene ( PS ), polyethylene terephthalate ( PET ) and styrene-acrylonitrile copolymers ( SAN ). Other designations are just brand names such as PLEXIGLAS®, others refer to the manufacturing process (such as GS for "cast" or XT for "extruded").

Acrylic glass (polymethyl acrylate; PMMA)

Trade names for acrylic glass

Due to patents, some companies use different trade names in different regions. Otto Röhm registered the Plexiglas® brand name in 1933. To this day, this is the registered brand name of Röhm GmbH in Europe and Asia. In the US, Altuglas International (Arkema Group) uses the name. Röhm therefore offers acrylic glass there under the name Acrylite® and the Arkema Group uses the names Altuglas® and Oroglas® in Europe.Other brand names for acrylic glass are Piacryl®, Deglas®, Hesalitglas®, Limacryl®, PerClax® and Vitroflex®.

The material was developed independently in different countries in 1928. It was first used in contact lenses in 1940. The hood of the Braun SK 4 turntable combinations was the first everyday product made of acrylic glass. It was launched in 1956.

Properties of acrylic glass

PMMA can be plastically deformed from a temperature of 100°C. It is suitable for machining (drilling, milling), can be excellently cut or engraved with CO2 lasers. Connections are possible by gluing and welding.The material is easy to color, weatherproof and aging resistant. Although acrylic glass is translucent , it absorbs UV rays and is therefore UV stable . However, it is more scratch-sensitive than glass or polycarbonate, but it can be polished to remove scratches .

When cleaning , it should be noted that although acrylic glass is resistant to acids, medium-concentration alkalis, petrol and oil, ethanol, acetone and benzene dissolve it.

Acrylic glass is more suitable for signs and advertising materials than other types of art glass because of its more attractive appearance and crystal-clear transparency.

Polycarbonate (PC)

Trade names for PC

The best-known brand names are Makrolon® and Lexan® , but there are also a number of other designations such as ASTALON, Carboglass™, Carbolux®, Macrolux®, Sicoklar® and Sparlux®.The chemist Alfred Einhorn discovered the material as part of his research as early as 1898. However, since he was involved in the development of narcotics, the substance did not interest him. It was not until 1953 that Bayer AG developed the plastic further and brought it onto the market as Makrolon® in 1958. In 1973 General Electric began manufacturing under the trade name Lexan®.

PC properties

PC is a crystal-clear plastic that is characterized by its high rigidity and dimensional stability and excellent resistance to weathering and aging. In addition, polycarbonate has the highest scratch resistance of all plastics.PC is less UV stable (yellowed) than acrylic glass. In practice, the higher scratch resistance and better resistance to chemicals compared to acrylic glass are important. PC can also be bent cold . Another advantage of PC compared to acrylic glass is its higher impact resistance and fire behavior. Polycarbonate panels meet the fire protection standard DIN 4102 B1 .

Due to the higher price (two to three times more expensive) and the lower transparency (PC scatters the light), the material is more likely to be used in aircraft windows, car headlight glass and greenhouse glazing, since break resistance and scratch resistance are important here. A typical product made of polycarbonate in the private sector is transparent corrugated sheets and double-wall sheets for cladding, as well as CDs and DVDs.

Polystyrene (PS)

Polystyrene is a translucent, robust plastic. Its breaking strength is approx. 10 times higher than that of real glass.PS does not splinter and can be easily processed like acrylic glass - whether cutting, sawing, drilling or gluing. In some cases, PS is even easier to work with than acrylic, which is why this material is also suitable for beginners.

In contrast to acrylic glass, however, polystyrene is absolutely not UV-compatible . It is therefore only suitable for indoor use.

Polyethylene terephthalate (PET) and styrene-acrylonitrile copolymers (SAN)

While PET is used almost exclusively for films and plastic bottles, SAN is also used as a "glass replacement". Light guides often consist of it, as do optic bodies such as sensors and transparent parts of food processors. SAN can also be used like acrylic glass for shower cubicle walls.SAN has higher strength , thermal resistance and scratch resistance than acrylic glass, but is less UV-stable , has lower impact strength and a slightly yellowish tint. Unlike polycarbonate, it is not suitable for clipping. Common brand names are Luran®, Lustran®, Styvex® and Suprel®.