"Through-print": screen printing and risography

Monday, April 15, 2019

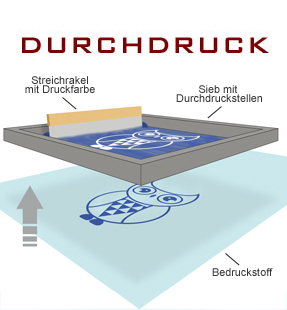

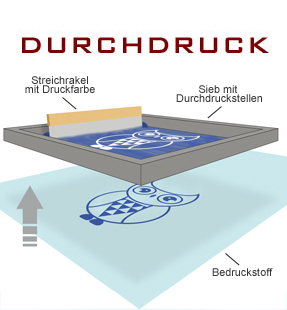

Through pressure is next to high pressure, planographic printing and gravure printing are one of the most important printing processes. With this printing process, the image areas of the printing form consist of the openings on a stencil carrier or a screen. The areas that are not to be printed are impermeable to ink. The best-known examples of this type of printing are screen printing and risography.

First the screen is coated with a photopolymer and exposed together with an image to be printed. The photopolymer hardens in the areas that are not to be printed. The printed image is then washed out with the water.

The color is now pressed onto the printing material with the rubber squeegee or squeegee through this template . A separate stencil is prepared for each color.

As a disadvantage , the first thing to mention is that the colors of a motif cannot be applied at the same time, only one after the other. In addition, gradients cannot be transferred. Screen printing is quite time-consuming and expensive, because several stencils have to be prepared for each multicolored motif. That is why screen printing is not suitable for very small or very large runs. For very large print runs, offset printing is preferred, which allows millions of printed products to be published cost-effectively in a short time.

With stencil printing there is no supporting screen, since the stencil is usually made of steel and stretched directly into the frame.

screen printing

Screen printing is a direct through-printing process in which the ink is applied to the substrate with a squeegee through a screen . The finer the screen, the more precisely the print motif is printed.First the screen is coated with a photopolymer and exposed together with an image to be printed. The photopolymer hardens in the areas that are not to be printed. The printed image is then washed out with the water.

The color is now pressed onto the printing material with the rubber squeegee or squeegee through this template . A separate stencil is prepared for each color.

Advantages and disadvantages of screen printing

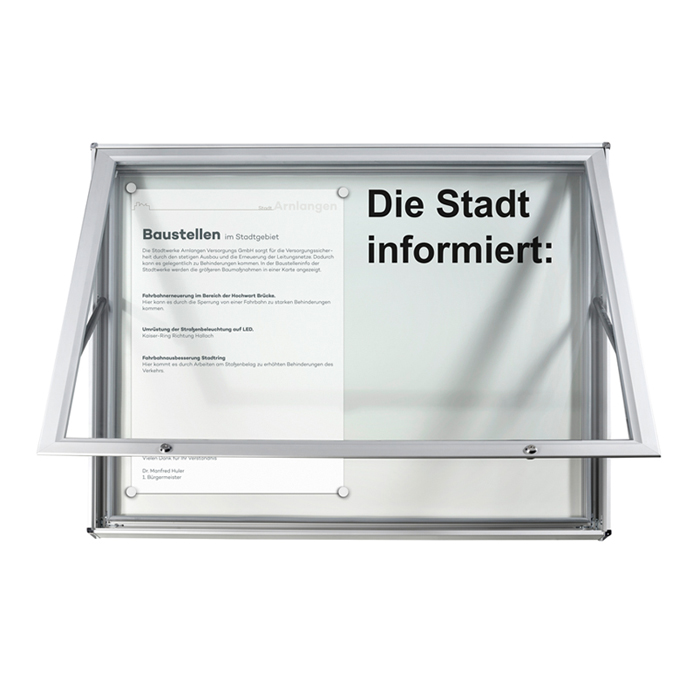

Screen printing has the obvious advantages . This type of printing can be used to print any material in any form, whether it is paper, plastic, textile, ceramics, metal, wood or glass. Screen printing is often used for textile printing (T-shirts, jackets, sweaters, banners and flags), for printing on advertising materials ( pens , key rings, lighters, etc.) or for printing signs . The colors applied are brilliant and long-lasting. Screen printing is suitable for large and small formats. It is also possible to print light colors on the dark printing material and the colors do not lose their brilliance.As a disadvantage , the first thing to mention is that the colors of a motif cannot be applied at the same time, only one after the other. In addition, gradients cannot be transferred. Screen printing is quite time-consuming and expensive, because several stencils have to be prepared for each multicolored motif. That is why screen printing is not suitable for very small or very large runs. For very large print runs, offset printing is preferred, which allows millions of printed products to be published cost-effectively in a short time.

Other forms of printing

With risography , the stencil to be printed is photographed with a special printer and a master foil is first created from this. Holes are lasered into this master foil at the points through which the ink is later to reach the material to be printed. Now the film is stretched on the drum and the drum is set in rotation. Risography is considered an ecological and environmentally friendly printing process.With stencil printing there is no supporting screen, since the stencil is usually made of steel and stretched directly into the frame.