"Gravure printing": Pad printing, rotary printing and sheet-fed gravure printing

Friday, March 15, 2019

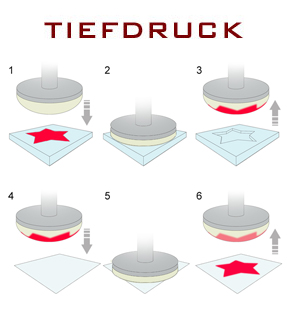

In addition to relief printing , gravure printing is one of the oldest printing processes. In contrast to relief printing, the image areas to be printed are not raised, but rather deepened in the printing form.

In addition to relief printing , gravure printing is one of the oldest printing processes. In contrast to relief printing, the image areas to be printed are not raised, but rather deepened in the printing form.How does the printing process work in gravure printing?

The printing forms are rotating steel cylinders covered with a base layer of copper. Engravable copper or a so-called Ballard skin is applied to this. The print image is cut in the printing form by means of etching, engraving or laser. The resulting indentations (called cups ) are filled with a color, the excess color is removed from the cylinder with a squeegee.The printing ink is only in the cells and is transferred to the printing material with high contact pressure. The deeper the cells are, the more color is applied and the more intense this color becomes. Each color needs a separate printing unit.

rotary printing and sheetfed gravure printing

A distinction is made between rotogravure and sheet-fed gravure. Rotogravure printing enables high printing speeds, while sheet-fed gravure printing is used for high-quality printing thanks to its color fastness. Intaglio printing is primarily used for high-volume print products (e.g. magazines, catalogues, decorative foils for furniture construction, wallpaper), in label and packaging printing, but also in the artistic field. Banknotes, securities and stamps are also produced using this process.pad printing

Intaglio printing is basically one of the direct printing processes. But there is also an indirect gravure printing - pad printing , in which the printing form is in an elastic pad made of silicone rubber. With this pad, the artwork is transferred like a stamp. This process is used for fine printing on uneven and small-format substrates, e.g. in the production of promotional gifts (stationery, lighters or ballpoint pens ), in the printing of dials on clocks, toys, crockery, model making, etc.Advantages and disadvantages of gravure printing

Although the gravure printing process is very old, it retains its usefulness to this day. High production speeds and print run stability of the printing forms are among the greatest advantages of gravure printing. High print quality, even inking and rich color depths are impressive, even compared to state-of-the-art digital printing .Disadvantages of this method include the high cost of the printing blocks and the time consuming production of the printing blocks. In addition, a sawtooth effect occurs during printing due to the cell shape, so that the edge sharpness in writing, for example, is poor. This is the characteristic feature of the gravure printing process.