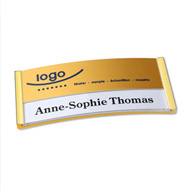

Laser engraving of metals

Laser engraving is the permanent labeling or marking of objects using a laser beam. The engraving is done without contact by removing material. The engraved motif remains smudge-proof, weatherproof and time-resistant. Which metals can be engraved? Does the surface need to be pre-treated?