"High pressure": letterpress, flexographic and stamp printing

Friday, March 1, 2019

From the history of high pressure

Letterpress is the oldest printing process in the world, originally called letterpress printing . Stamp printing, on which this process is based, was already known in antiquity. In the 15th century in Europe, the book press with movable type for book printing was invented by Johannes Gutenberg. Letterpress was the dominant printing process until the mid-1970s. A typical feature of letterpress is crushed edges on the printed letters. Today, letterpress printing is hardly ever used.

Printing process and possible uses

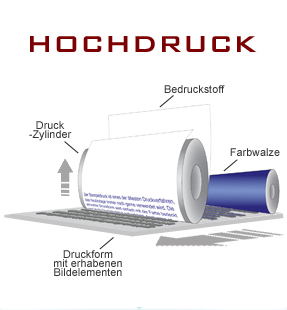

Relief printing is one of the direct printing processes and is referred to as high relief because the areas to be printed rise above the area not to be printed on the printing form. The print motifs are covered with paint and pressed directly onto the paper. The print image must be applied to the printing form in a mirror-inverted manner. The printing forms can be either hard (wood, metal) or soft (rubber, linoleum).The woodcut, the wood engraving and the linocut are currently only used in the artistic field. Classic letterpress is now widely replaced by offset printing and is used almost exclusively for the production of very sophisticated prints or artistically designed books.

Advantages and disadvantages of high pressure

The replacement of letterpress by offset printing has important reasons. On the one hand, this process is very time-consuming and expensive : the production of the printing plates and their preparation before they are set up is expensive. Furthermore, the set needs a lot of space for storage. The letters are bound in the standing type and cannot be used elsewhere.The following advantages should be mentioned: since the print motif is usually very sharp in letterpress, small font sizes can also be displayed well. In addition, no dampening is used here (in contrast to offset) and punching, embossing or perforating is possible here.

Other forms of high pressure

Other forms of printing developed on the basis of letterpress printing - indirect letterpress (or letterset), flexographic printing and today's stamp printing.Letterset is an indirect letterpress process. The artwork is printed using a right-sided printing block. The printing block is bent and attached to the printing cylinder. The print image is then transferred to a rubber blanket and then from the rubber blanket to the print template. Indirect letterpress printing is similar to offset printing, but the main difference is that no water is used here, as is necessary with offset printing. The letterset is too expensive in terms of material and time and has therefore become uneconomical, but is still used in continuous printing and in the packaging industry.

The name flexo printing makes it immediately clear that it is a flexible form of printing. Flexographic printing is a rotary direct printing process whose printing form consists of a photopolymer. Thanks to its flexibility, this process is still used in a variety of ways today and can be used to print many different materials: plastic packaging, foils, serviettes, wallpaper or corrugated cardboard, materials with crunchy surfaces and textile fabrics. Flexographic printing is also used for packaging printing (boxes, bags, paper carrier bags).

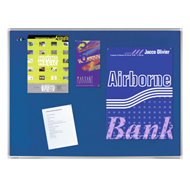

Stamp printing is one of the oldest printing processes that is still popular today. The individual printing form is simply covered with the color and pressed onto the printing material. Even though there is no legally binding requirement for companies in Germany to have a company stamp, many companies choose to have at least one stamp with the company name and company logo. In particular, certificates and important letters can be signed in order to distinguish them from forgeries. Address and date stamps as well as IBAN stamps are also very popular uses of this printing process.