Laser engraving of aluminium

Sunday, November 1, 2020

Aluminum is a silvery-white light metal and the most common metal in the earth's crust. It is relatively soft and tough, very light, electrically and thermally conductive, paramagnetic. Aluminum is base; it reacts with air and water in freshly cut areas and forms a protective layer (passivation) that protects the aluminum from corrosion.

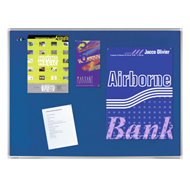

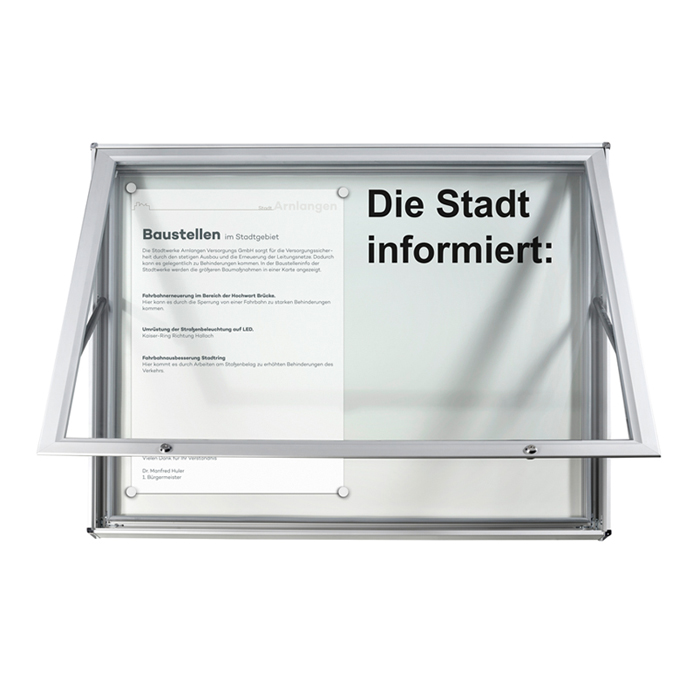

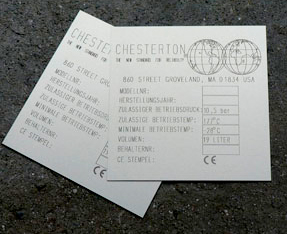

Aluminum is a silvery-white light metal and the most common metal in the earth's crust. It is relatively soft and tough, very light, electrically and thermally conductive, paramagnetic. Aluminum is base; it reacts with air and water in freshly cut areas and forms a protective layer (passivation) that protects the aluminum from corrosion.Thanks to its properties, aluminum and its alloys have become one of the most popular materials in metal goods manufacturing, electrical engineering and power engineering. Aluminum is used for heat exchangers, cables and electrical lines, pipes, cans and household items, components in machines, vehicles and airplanes, company signs and type plates are made from aluminium.

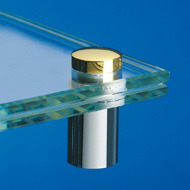

Anodized and brassed aluminum

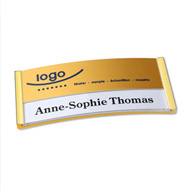

In principle , laser engraving can also be done on aluminum and aluminum alloys without a coating. With the anodized aluminum, however, a particularly good contrast can be achieved. Aluminum components are labeled by laser engraving, aluminum nameplates are made and much moreMaterials specially designed for laser engraving are AlumaMark® and DuraBlack® . These are aluminum plates in various shapes and colors that are provided with a special layer for quality laser engraving. Thanks to this layer, the motif is engraved in black on the AlumaMark® plate. On DuraBlack®, on the other hand, a white engraving is created on a black background.

The brass-plated aluminum or the brass-plated steel create a gold-colored engraving.

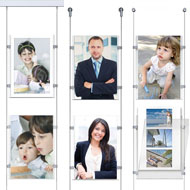

Aluminum composite panels

Aluminum composite panel or Alu-Dibond is another well-known aluminum product. You can also engrave the Alu-Dibond, but not with the laser, but by special milling . They are so-called sandwich panels, they consist of several layers. The outer layers are 0.3mm aluminum plates thermally bonded to a plastic layer. With all other dimensions being the same, the aluminum composite panel is therefore lighter than the aluminum panel. The overall thickness of the aluminum composite panel can be from 2 mm to 6 mm.Since aluminum composite panels are very robust, durable, UV and weather resistant, they are often used for outdoor advertising and signage, kitchen splashbacks, partition walls. Alu-Dibond is particularly easy to print: the images printed on Alu-Dibond are very popular today.