Laser engraving of metals

Thursday, October 15, 2020

Laser engraving is the permanent labeling or marking of objects using a laser beam. The engraving is done without contact by removing material. The engraved motif remains smudge-proof, weatherproof and time-resistant.

Laser engraving is the permanent labeling or marking of objects using a laser beam. The engraving is done without contact by removing material. The engraved motif remains smudge-proof, weatherproof and time-resistant.Laser engraving allows a very detailed representation even on the smallest parts of the objects. The engraving can be done on different materials: wood, glass, acrylic glass, leather and metal.

How does metal laser engraving work?

Depending on how the metal surface is coated, different effects can be achieved with the laser inscription. In the case of painted or anodized metals, only the coating is removed.However, uncoated metals can also be engraved with a laser. However, you need a more powerful laser engraving machine to remove enough material from the hardest steel, for example, and achieve the desired contrast.

Metal objects must be pre-treated before engraving. The treatment is to be carried out with a special paste or with a spray. The metal is coated thinly and evenly with it and then engraved. If the metal is painted or colored, the paint or paint may need to be removed if you want to engrave not just the top layer of paint or paint, but the actual material as well.

What metals can you engrave?

In principle , almost all metals and alloys are suitable for laser engraving. Particularly excellent results can be seen on titanium and stainless steel, but anodised aluminum, aluminum composite, brass, copper and bronze can also be lasered well.Areas of application for laser marking of metals

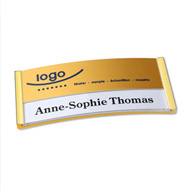

The lettering engraved with the laser remains abrasion-resistant and permanent , which is why this marking method is ideal for metals. Whether in the automotive industry, mechanical engineering, medical technology or electrical engineering - laser inscriptions are required to enable permanent marking and coding.Metal engraving is also used in many other areas: for door signs, nameplates and plaques; jewelry (eg rings, bracelets) and watches; Promotional items (eg key fobs, lighters, etc.); souvenirs (e.g. love locks, caskets, knives); Trophies and awards and much more.