Multipanel UK - Aluminium- und Stahlverbundplatten aus England

Dienstag, 15. Dezember 2020

Multipanel UK Alupanels sind Aluminumverbundplatten mit klassischem Aufbau: LDPE-Kern mit zwei Aluminiumdeckschichten. Sie können für die unterschiedlichsten Anwendungen und Anforderungen verwendet werden.

Multipanel UK Alupanels sind Aluminumverbundplatten mit klassischem Aufbau: LDPE-Kern mit zwei Aluminiumdeckschichten. Sie können für die unterschiedlichsten Anwendungen und Anforderungen verwendet werden.Kern der Aluminumverbundplatten

Der Kern der Alupanel-Platte ist ein 100% LDPE-Kern, der die Basis für die Grundfestigkeit und Steifigkeit schafft. Grundsätzlich gilt: ein steifer / stabiler Kern wird später die Biegesteifigkeit der Verbundplatte unmittelbar beeinflussen.Für Anwendungen, bei denen eine spezielle Brandschutzklassifizierung nach B1 (EN 13501-1) notwendig ist, können diese Platten auch mit einem speziellen sehr umweltfreundlich hergestellten und leichten B1 Kern ausgestattet werden.

Deckschichten der Aluminumverbundplatten

Die Deckschichten einer Aluminumverbundplatte beeinflussen nach dem Kern maßgeblich die Eigenschaften der Platte. Es kommen die Alu-Deckschichten in den Stärken 0.50 / 0.30 / 0.26 / 0.20 / 0.15 mm zum Einsatz. Eine Besonderheit stellen Deckschichten aus Stahl (diese sind magnetisch) dar.

Worauf sollte man bei der Auswahl der Verbundplatten achten?

Die Haltbarkeit wird beeinflusst von allen äußeren Einflüssen. Sorgsames Wählen der Verbundplatte, dem Einsatzort und der Einsatzart entsprechend, wird also immer wichtiger und sollte keinesfalls vernachlässigt werden.Der Einsatzort (innen oder außen), die Einsatzrichtung (UV-Strahlung) und spätere mechanische Belastungen müssen bei der Auswahl der richtigen Platte immer berücksichtigt werden. Nicht immer ist die Auswahl aufgrund des Preises zielführend.

Bei der richtigen Wahl des Plattentyps, sollten auch weitere spezielle Anforderungen berücksichtigt werden.

Soll die Platte bedruckt werden? Prinzipiell können mit modernen Drucksystemen alle Verbundplatten gut bedruckt werden. Speziell für den Digitaldruck ausgewiesene Platten haben aber noch weitere besondere Eigenschaften wie z.B. einen leicht entfernbaren Schutzliner, der hilft, den Workflow zu verbessern und weniger statische Aufladung verursacht. Spezialitäten, wie Oberflächen speziell für den Druck mit Latextinten, sind die neuesten Eigenschaften, die man auch berücksichtigen sollte.

Muss die Platte zum Abkanten rückseitig mit V-Nuten eingefräst werden, sollten sicherheitshalber nur Deckschichten von 0.26, 0.30 oder 0.50 mm verwendet werden.

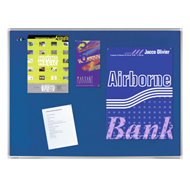

Magnetische Stahlverbundplatte

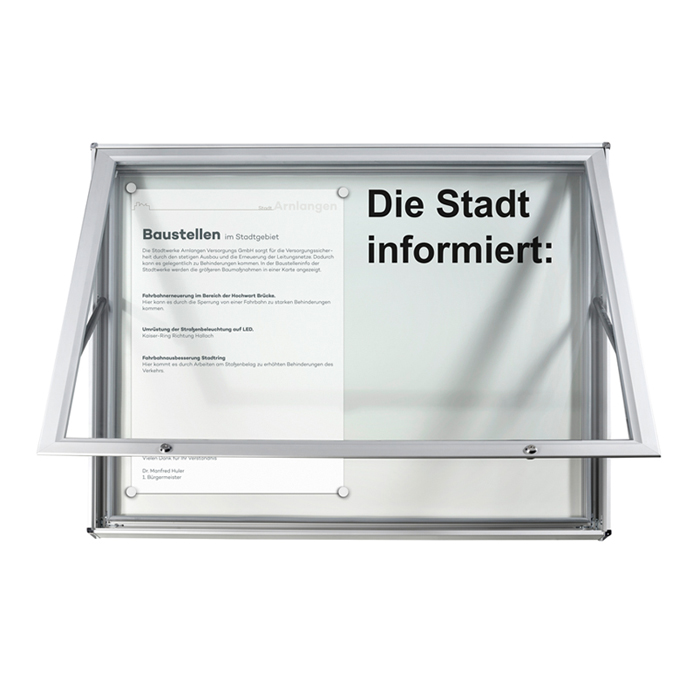

Eine spezielle Eigenschaft bietet magnetische Stahlverbundplatte "Multishield". Zwei 0.25 mm starke Deckschichten aus galvanisiertem Stahl bieten genug magnetische Gegenkraft für jeden handelsüblichen Magneten. Selbstverständlich kann diese Platte nach dem V-Nuten auch abgekantet werden.Der Einsatz als magnetische Pinnwand ist aber nicht die einzige Besonderheit von Multishield. Eine Seite ist digital bedruckbar und eine Seite kann sofort als Whiteboard verwendet werden! Die Montage ganzer Wände ist mittels Magneten damit denkbar einfach – ganz ohne Abstandshalter.

Einsatzorte sind: Whiteboardwände in Konferenzräumen, Magnetische Pinnwände, Rettungsbeschilderungen, Ladenbau, Verkleidungen, Sani-Konzepte, Magnetische Wechselrahmen u.v.m.

Aluverbundplatte mit Lasergravur

Die Oberfläche der Multipanel UK Platten kann auch mit einem hervorragenden Ergebnis lasergraviert werden. Zum Einsatz kommt z.B. ein 40 Watt CO2 Laser.Tipp für die Lasergravur von Alu-Verbundplatten: die besten Ergebnisse und somit eine schön silbrig glänzend gravierte Fläche erzielt man im unteren Bereich der Laser-Leistung.

Weitere Einsatzbereiche für Aluverbund

Aluverbund in seiner Vielfalt bietet für fast jede Anwendung eine Möglichkeit, tolle Ergebnisse zu erzielen und jederzeit ein einzigartiges fertiges Produkt anzubieten.Das britische Unternehmen Multipanel UK spezialisiert sich auf permanente Entwicklung innovativer Aluverbund-Produkte und die Entwicklung neuer und interessanter Anwendungsmöglichkeiten.

Modernste Produktionsverfahren -jederzeit ausgerichtet auf die Einhaltung geltender Emissionsrichtlinien- verstehen sich natürlich von selbst und machen Multipanel UK zu einem der führenden Aluminumverbundplatten-Herstellern weltweit.