Welche Druckarten gibt es?

Freitag, 15. Februar 2019

Es gibt heutzutage kaum Gegenstände, die nicht bedruckbar sind. Ob aus Papier, Kunststoff, Metall oder Textilien - je nach Material und Zweck werden zum Bedrucken verschiedene Druckverfahren und -techniken eingesetzt. Jede Druckart hat eigene Besonderheiten sowie Vor- und Nachteile.

Darüber hinaus ist mit der Entwicklung der Technologien eine neue Druckart namens Digitaldruck entstanden - der Druck erfolgt da mittels eines Computers und eines Druckers. Obwohl es dabei keine "richtige" Druckform gibt, wird der Digitaldruck auch zu den Drucktechniken als fünftes Druckverfahren gezählt.

Beim indirekten Druckverfahren wird das Druckbild zuerst auf einen Zwischenträger (z.B. auf Gummituchzylinder) angebracht und nur danach auf das bedruckende Material. Hier kann man Letterset, Tampondruck und Offsetdruck nennen.

Druckverfahren je nach Druckform

Je nach Verhältnis, in dem die Druckelemente zu der Druckform stehen, unterscheidet man zwischen den vier Hauptdruckverfahren: Hochdruck, Tiefdruck, Flachdruck und Durchdruck. Diese 4 klassischen Druckarten sind auch in der deutschen DIN 16500 definiert.Darüber hinaus ist mit der Entwicklung der Technologien eine neue Druckart namens Digitaldruck entstanden - der Druck erfolgt da mittels eines Computers und eines Druckers. Obwohl es dabei keine "richtige" Druckform gibt, wird der Digitaldruck auch zu den Drucktechniken als fünftes Druckverfahren gezählt.

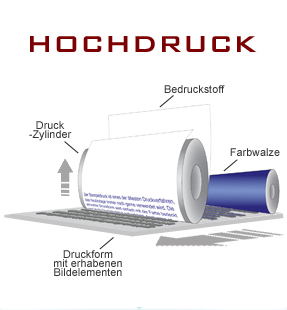

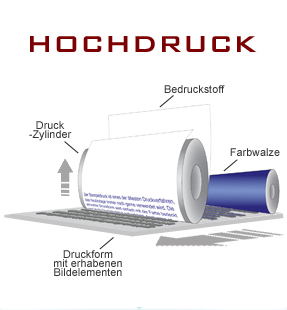

1. Hochdruck

Das älteste Druckverfahren ist Buchdruck, oder auch Hochdruck genannt. Es wird so genannt, denn die druckenden Elemente liegen auf einer höheren Ebene als die nicht zu druckenden Stellen. Auf der Basis des Hochdrucks sind weitere Druckarten entstanden – indirekter Buchdruck (oder Letterset), Flexodruck und Stempeldruck.

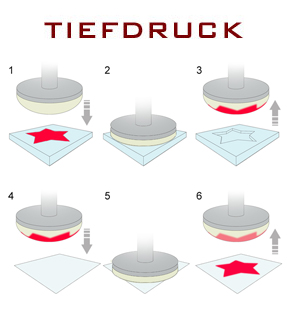

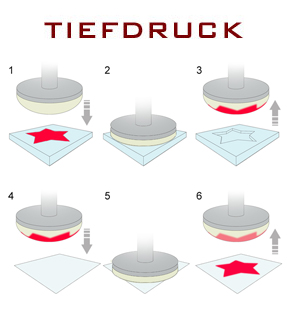

2. Tiefdruck

Im Gegensatz zu dem Hochdruck werden bei dem Tiefdruck die zu druckenden Bildstellen nicht gehoben, sondern in der Druckform vertieft. Der Tiefdruck wird vor allem bei Druckerzeugnissen mit hoher Auflage, im Etiketten- und Verpackungsdruck verwendet. Banknoten, Wertpapiere und Briefmarken werden auch in diesem Verfahren produziert. Zu dieser Druckart gehört auch Tampondruck, bei dem sich die Druckform in einem elastischen Tampon aus Silikonkautschuk befindet.

3. Flachdruck

Beim Flachdruck liegen die zu druckenden Stellen und die Druckform auf einer Ebene. Das bekannteste und populärste Verfahren des Flachdrucks ist gegenwärtig Offsetdruck. Er charakterisiert sich durch hohe Geschwindigkeit und Wirtschaftlichkeit, die es erlauben, in der kurzen Zeit die Druckerzeugnisse sogar in Millionenauflage kostengünstig herauszugeben. Dieses Verfahren eignet sich ideal für den Druck von Büchern, Tageszeitungen, Katalogen, Flyer u.a. Druckartikel, die in größerer Auflage produziert werden sollten.

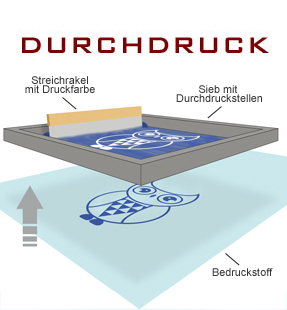

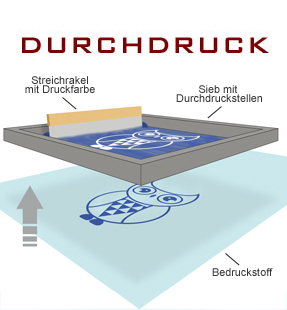

4. Durchdruck

Beim Durchdruck bzw. beim Siebdruck wird die Farbe durch ein Gewebe oder durch ein Sieb auf den Bedruckstoff aufgetragen. Mit dieser Druckart kann man beliebige Materialien in beliebiger Form bedrucken. In der Werbeartike-Branche ist diese Druckart sehr beliebt. Ob T-Shirts, Baumwolltaschen, Kugelschreiber oder Regenschirme - mit Siebdruck kann man fast alles in hochwertiger Qualität bedrucken lassen.

5. Digitaldruck

Das neuste Druckverfahren ist der Digitaldruck. Eine digitale Druckvorlage wird dabei mit dem Computer erzeugt und mittels des Druckers direkt auf das zu druckende Material übertragen. Im Gegensatz zum Offsetdruck wird beim Digitaldruck keine statische Druckform benötigt, was einen günstigen Druck in kleinster Auflage (ab 1 Stuck) ermöglicht. Der Digitaldruck hat sich in Bereichen Fotobücher, Kalender, Poster, Schilderdruck usw. fest etabliert. Als Drucktechniken unterscheidet man hier zwischen Tintenstrahldruck, Laserdruck, Sublimationsdruck und 3D-Druck.Druckverfahren je nach Übertragungsweg

Je nach Übertragungsweg unterschiedet man zwischen 2 Druckverfahren – direktes und indirektes. Das direkte Druckverfahren bedeutet, dass das Druckmotiv gleich von der Druckform auf das Druckmaterial angebracht wird. Zu direkten Druckverfahren gehören Siebdruck, Flexodruck, Stempeldruck, Tiefdruck und UV-Direktdruck.Beim indirekten Druckverfahren wird das Druckbild zuerst auf einen Zwischenträger (z.B. auf Gummituchzylinder) angebracht und nur danach auf das bedruckende Material. Hier kann man Letterset, Tampondruck und Offsetdruck nennen.