Alu-Dibond Schilder im Vergleich

Freitag, 1. Oktober 2021

Die Alu-Dibond-Schilder werden im Innen und Außen als Türschilder, Werbeschilder, Firmenschilder und sogar als Galerie-Bilder eingesetzt. Diese werden immer mehr populärer, denn Alu-Dibond® hat viele Vorteile. Machen wir uns mit diesem Material näher bekannt.

Die Alu-Dibond-Schilder werden im Innen und Außen als Türschilder, Werbeschilder, Firmenschilder und sogar als Galerie-Bilder eingesetzt. Diese werden immer mehr populärer, denn Alu-Dibond® hat viele Vorteile. Machen wir uns mit diesem Material näher bekannt.Was ist Alu-Dibond®?

Als Vorgänger des Alu-Dibond® gelten Verbund-Platten, die früher Alucobond hießen und in der Architektur genutzt wurden. Dann wurde dieses Material als Marke Dibond® patentiert, die der 3A Composites GmbH aus Singen gehört, und ist heutzutage weltbekannt. Die Verbundplatten werden auch Aluminium Sandwichplatten genannt und bestehen aus 3 Schichten. Die äußeren Schichten sind aus 0,3 mm starkem Aluminium, die mittige Schicht – aus einem Polyethylenkern, der mit Aluminium thermisch verbunden ist.So ein Verbund von Aluminium und Polyethylen macht Dibond®-Platten viel leichter und preisgünstiger als Alu-Platten, steif und äußerst langlebig. Von vornherein wurde Alu-Dibond® speziell für die Produktion von Werbeschildern konzipiert, so sind die Verbundplatten für Anwendung im Außen vortrefflich geeignet. Sie sind sehr robust, UV- und witterungsbeständig, dazu noch feuerfest und einfach zu handhaben.

Arten von Alu-Dibond®

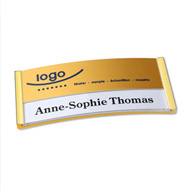

Die Arten von Alu-Dibond® unterscheiden sich durch Oberfläche, Farbe und Stärke.Eine gewöhnliche Oberfläche des Alu-Dibond® ist glatt und weiß, man kann auch farbige Ausführungen finden. Die Aluminium-Schicht kann aber speziell bearbeitet – gebürstet (oder brushed) – werden. Diese Ausführung heißt Butlerfinish® und zeichnet sich durch eine Metalloptik aus, die besonders edel und hochwertig wirkt. Die gebürstete Oberfläche dieser Platten ist häufig in Silber und Gold zu treffen, es gibt auch Ausführungen in anderen Farben, zum Beispiel Kupfer, Edelstahl, Rosegold, Anthrazit. Butlerfinish® verfügt über alle Eigenschaften von Alu-Dibond®.

Was die Stärke anbetrifft, können die glatten Alu-Verbundplatten von 2 mm bis 6 mm stark sein, Alu-Dibond® Butlerfinish® ist in der Regel 3 mm stark.

Wie kann man Alu-Dibond® bedrucken?

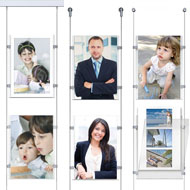

Dank seinen Eigenschaften wird Alu-Dibond® häufig für die Herstellung der großformatigen Schilder mit Druck angewendet, zum Beispiel beim Messeaufbau oder als Ladenschild, Werbeschild. Da der Alu-Dibond® Druck spiegelungs- und reflexionsarm ist, präsentiert er hochwertige Fotos, Kunstdrucke und Grafiken mit besonders edler und effektvoller Optik.

Dank seinen Eigenschaften wird Alu-Dibond® häufig für die Herstellung der großformatigen Schilder mit Druck angewendet, zum Beispiel beim Messeaufbau oder als Ladenschild, Werbeschild. Da der Alu-Dibond® Druck spiegelungs- und reflexionsarm ist, präsentiert er hochwertige Fotos, Kunstdrucke und Grafiken mit besonders edler und effektvoller Optik.Ungeachtet des Druckverfahrens, mit dem die Alu-Dibond®-Platten bedruckt werden können, können die glatten Alu-Dibond®-Platten zweiseitig und die Butlerfinish®-Platten nur einseitig bedruckt werden.

Im digitalen Direktdruck wird Ihr Motiv mittels UV-Druck direkt auf die Platte gedruckt. Dabei entsteht ein leicht mattes Druckbild; die weißen Stellen werden nicht gedruckt, es bleibt die metallische Oberfläche sichtbar. Besonders ausdrucksvoll wirken Alu-Dibond®-Schilder auf der Butlerfinish®-Platte.

Die Verfahren Fineart-Druck und Kaschieren eignen sich besser für die glatten Alu-Dibond®-Platten. Die beiden Verfahren werden für die Bedruckung von Butlerfinish®-Platten nicht empfohlen, denn dabei geht der gebürstete Metalleffekt der Oberfläche verloren.

Beim Fineart-Druck wird das Foto zuerst auf das hochwertige Fotopapier gedruckt. Das bedruckte Papier wird dann matt oder glänzend laminiert. Zuletzt wird das laminierte Bild auf die Platte kaschiert. So entstehen die Alu-Dibond®-Schilder stilvoll, kratzfest, mit brillantem und elegantem Look.

Bei der Druckart Kaschieren wird das Foto auf die Folie, oft selbstklebend, gedruckt und dann auf die Platte aufgezogen. Dabei kann das Motiv gänzlich bedruckt werden oder konturgeschnitten sein. Die Qualität solcher Alu-Dibond®-Schilder ist ähnlich den Schildern auf dem Fotopapier. Es ist aber zu beachten: vor dem Kaschieren muss die Platte schmutz-, fett- und staubfrei sein.

Einige Hersteller von Alu-Dibond®-Schildern bieten auch Lackieren. Dabei werden die Schilder überlackiert, danach mit Nassschleifpapier abgeschliffen und zuletzt wird davon der Schleifstaub entfernt.

Unabhängig von der Oberfläche können die Alu-Dibond®-Platten im Siebdruckverfahren bedruckt werden.

Befestigungsarten für Alu-Dibond-Schilder

Es gibt verschiedene Möglichkeiten, das Alu-Dibond®-Schild an die Wand zu befestigen.

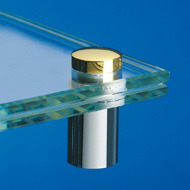

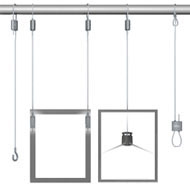

Es gibt verschiedene Möglichkeiten, das Alu-Dibond®-Schild an die Wand zu befestigen.Sehr populär sind Wand-Abstandshalter. Die Abstandhalter werden aus Messing gefertigt und in Silber, Gold oder Chrom veredelt. Das Set beinhaltet 4 Stück und ein komplettes Montageset. Um das Alu-Dibond®-Schild damit an die Wand anzubringen, sollte es in den Ecken gebohrt werden. Wenn Sie Ihr Schild nicht bohren möchten, können Sie es mit einem Klemmsystem, mit Alu-Schienen, Spiegelblech bzw. Einhaker oder mit einem Klebestoff montieren.

Wie die Wand-Abstandshalter werden Klemmen von vorne sichtbar. Die Klemmen eignen sich für die Schilder mit der Stärke von 3 mm bis 10 mm. Für die Alu-Schienen, Spiegelblech bzw. Einhaker muss man die Wand bohren, Schrauben setzen und dann das Schild einfach aufhängen.

Da Alu-Dibond® extra leicht ist, kann das Schild als selbstklebend montiert werden. Wegen des geringen Gewichts wird für die Schild-Befestigung nur wenig Klebestoff verwendet. So kann das Schild später bei Bedarf ziemlich leicht demontiert werden.